ABOUT US

Welcome to the Chapman Maker company! We were founded in 2016, with a SGS certification and an ISO 9001 quality management system.

We focus on plastics molding development; thin and thick wall molding, tight tolerance molding, LSR molding, new product development and assembly. We serve a number of markets including Industrial, Automotive, Medical, Electronics, Defense, Transportation and Consumer. We consistently exceed our customer’s expectations by empowering all associates and creating a culture that embraces improvement, lean manufacturing and supply-chain collaboration to ensure maximum value to our customers.

- 80 People

- 5-30 Day Lead Time

- 300-500K/Month Injection Capacity

- 35-50 Sets/Month Mold Capacity

PRODUCT

-

-

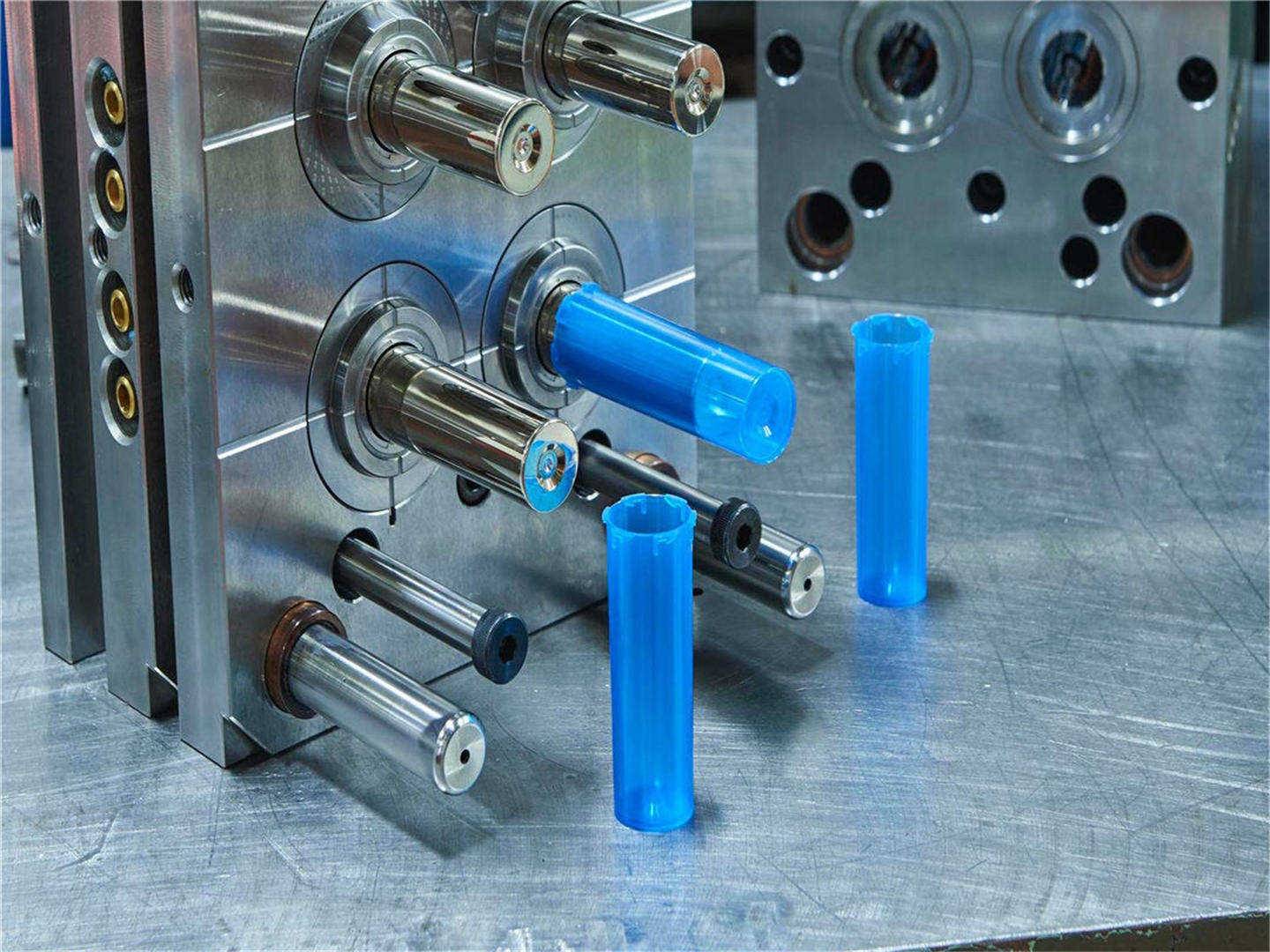

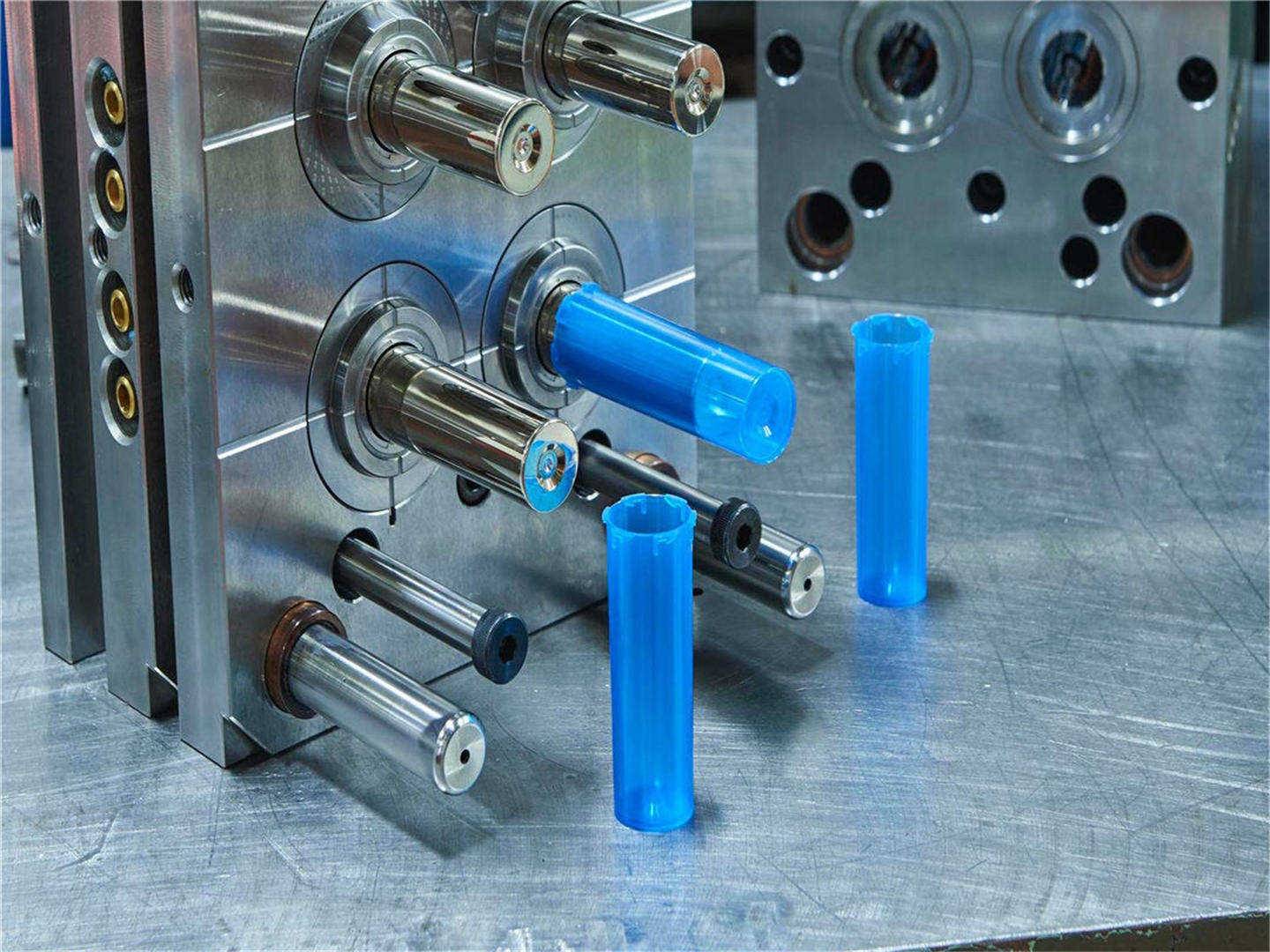

Plastic Mould & Injection

Our molding facilities offer flexibility in running all types of thermoplastic materials. We specialize in manufacturing products for a broad range of applications as well as for specific industries including medical, electronic equipment, connectors, industrial, defense, transportation, and consumer.

With four plants and 50+injection ranging from 60 to 500 tons, we can manufacture components as small as .75 ounces up to enclosures as large as 80 ounces (5 lbs). We can assist you in optimizing and improving your product design to achieve the best possible results to meet your component requirements.

-

Product Development

Whatever stage you are in during product development our team is ready to assist and make recommendations for your designs to reduce molding and secondary service costs.

We Provide:

Design for Manufacturability

Rapid Prototyping

Vertically Integrated Manufacturing

Thick and Thin Wall Molding

Decorating & Screening

Material Selection

Meet all your

Our in-house secondary operations eliminate outside vendors, saving a significant amount of lead-time and costs for all your products.

In-House Secondary Operations:

Part Joining: Adhesive Bonding, Heat Staking

Ultrasonic Welding

Pad Printing and Decorating

Hot Stamping

Mechanical & Electro-Mechanical Assemblies and Testing